PVC Alu Blister Packing Machine

Product Details:

- Type Blister Packaging Machines

- Material SS

- Feature Rust Proof Heavy Duty Machine Durable Highly Efficient Less Power Consumable

- Auxiliary Packaging Machine Type Other

- Computerized Yes

- Automatic Grade Automatic

- Control System PLC Control

- Click to View more

PVC Alu Blister Packing Machine Price And Quantity

- 1 Unit

PVC Alu Blister Packing Machine Product Specifications

- Rust Proof Heavy Duty Machine Durable Highly Efficient Less Power Consumable

- Electric

- 5000 Watt (w)

- Yes

- 1 YEAR

- PLC Control

- 230 Volt (v)

- Other

- 1900 Kilograms (kg)

- Automatic

- Blister Packaging Machines

- SS

- 3000X1000X1500 Millimeter (mm)

- Silver

PVC Alu Blister Packing Machine Trade Information

- Letter of Credit (L/C) Cash in Advance (CID) Cheque Cash Advance (CA)

- 5 Unit Per Month

- 60 Days

- Contact us for information regarding our sample policy

- WOODEN BASE/WOODEN BOX

- Western Europe Middle East Central America South America Asia Eastern Europe North America Australia Africa

- All India

- ISO 9001:2008 CERTIFIED WITH cGMP STANDARDS. CE Certification.

Product Description

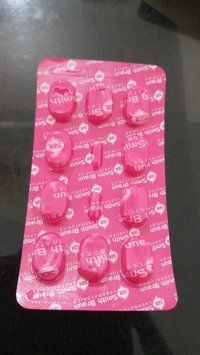

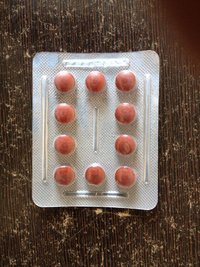

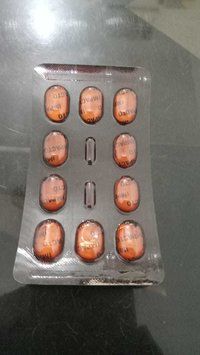

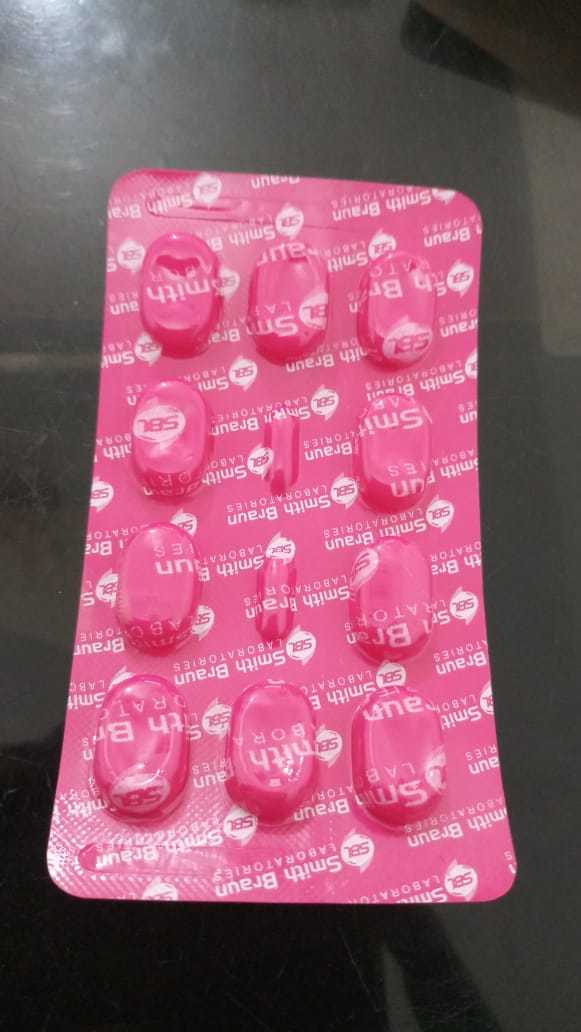

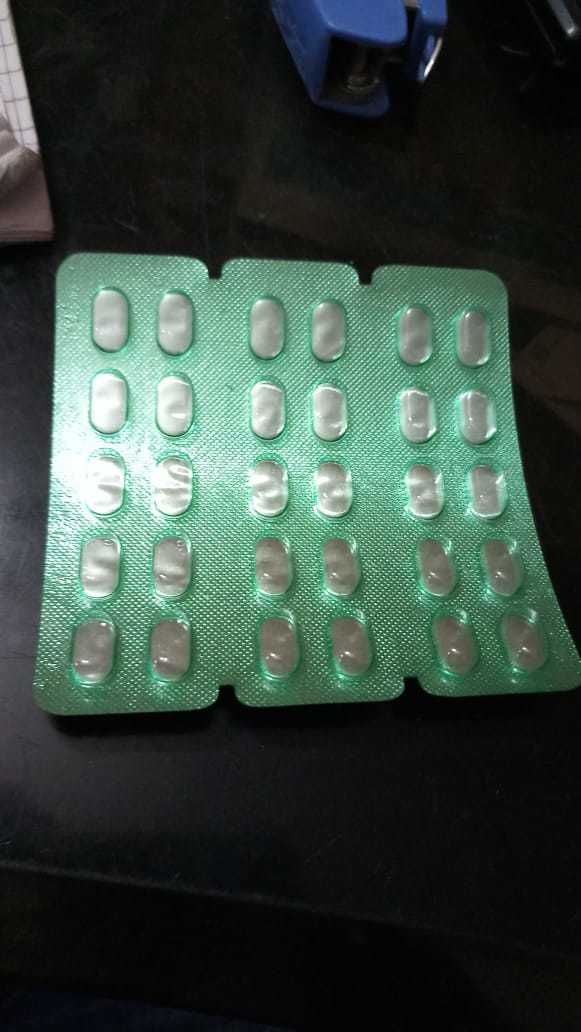

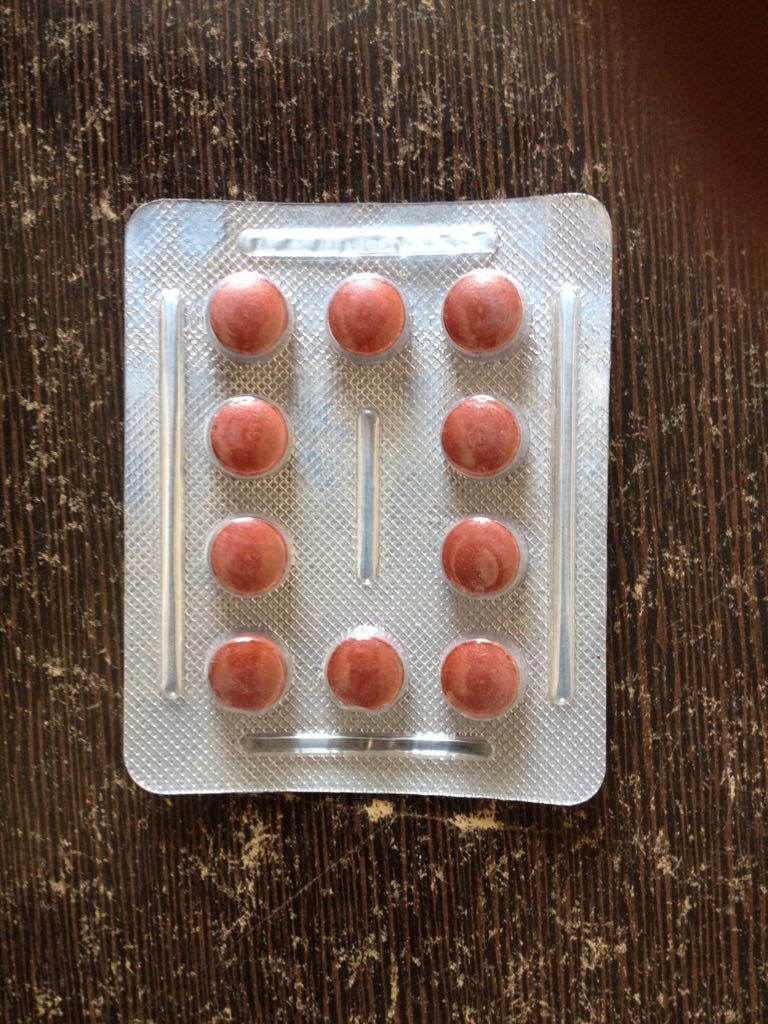

PVC ALU Blister Packing Machine is ideal tools for the pharmaceutical industry for the packing of oral tablets, capsules, hard and soft gelatine and ampoules. This machine is manufactured under stringent quality control process to ensure years of trouble-free production. The machine works on the flat forming & rotary sealing principle for delivering higher outputs. PVC ALU Blister Packing Machine ensures total synchronization of timings between sealing of aluminium foil and PVC base web. The blister pack may either be collected in bins or may be conveyed over a belt for further handling. The machine could be linked to a cartoner.

SPECIAL FEATURES :

- Production capacity upto 2500 Tablets per/min.

- Production capacity upto 250 Ampoules-Vials per/min.

- Best built quality

- Rigid Design

- Full GMP Standards satisfying with all Stainless steel cladding

- Hi-speed with smoothness & noiseless performance

- Blister Inspection System With Rejection System

- Perforation

- Auto Feeder for Ampoule - Vials

- Inkjet Printer

- Batch Code Letter Embossing Attachment

- Print Registration Control for Pack to Print

- Plc Based Operation

- Scada System Compliance for 21 Cfr With Ipc

- Acrylic & Polycarbonate Guards

Technical Specification

| Base Film Width Max. | 210 MM |

| Base Film Thickness Max. | 0.25 -0.4 MM |

| Base Film Material | PVC / PVDC / ACLAR / OPAQUE / TRIPLEX |

| Sealing Foil Width Max. | 206 MM |

| Sealing Foil Thickness Max | 0.02 - 0.04 MM |

| Sealing Foil Material | Aluminum / CR Foil / Laminated Paper |

| Pack Length | 200 MM |

| Pack Width | 100 MM |

| Forming Depth | 16 MM / 20 MM for Ampule / Vial |

| Max. Output | 200000 Ampoule-Vials per shift (8 Hr.) |

| Cutting Speed | upto 1200000 Tablet - Capsules per shift(8 Hr.) |

| Electrical Input | upto 100 Strokes per/min. for Tablet-Capsules |

| Machine Dimensions (LXWXH) | upto 30 Strokes per/min. for Ampoule - Vials |

Compressed Air Requirement

| CFM | 15 CFM |

| Pressure | 6 bar |

| Chilled Water Requirement | 100 Liters of chilled Water / Hour at 16° C Temperature |

| Additional Safety | Air Dryer, Voltage Stabilizer |

Other Products in 'Blister Packing Machine' category

|

HELIOS CONCREW PRIVATE LIMITED

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese